Challenges and Development of Subsea Production Systems

Challenges and Development of Subsea Production Systems

Blog Article

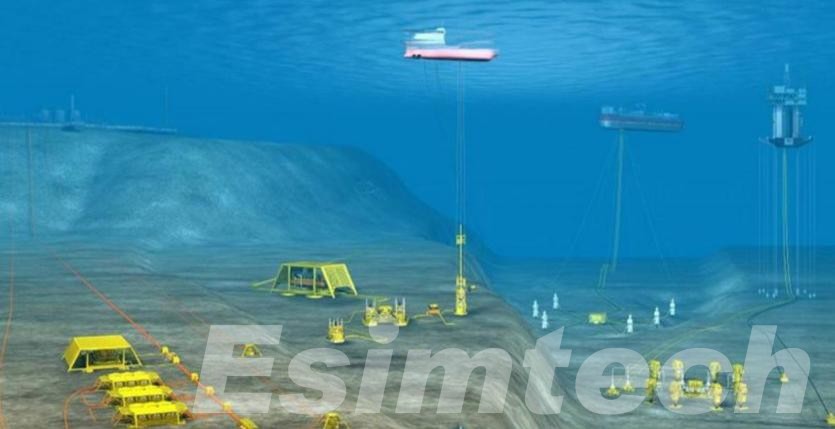

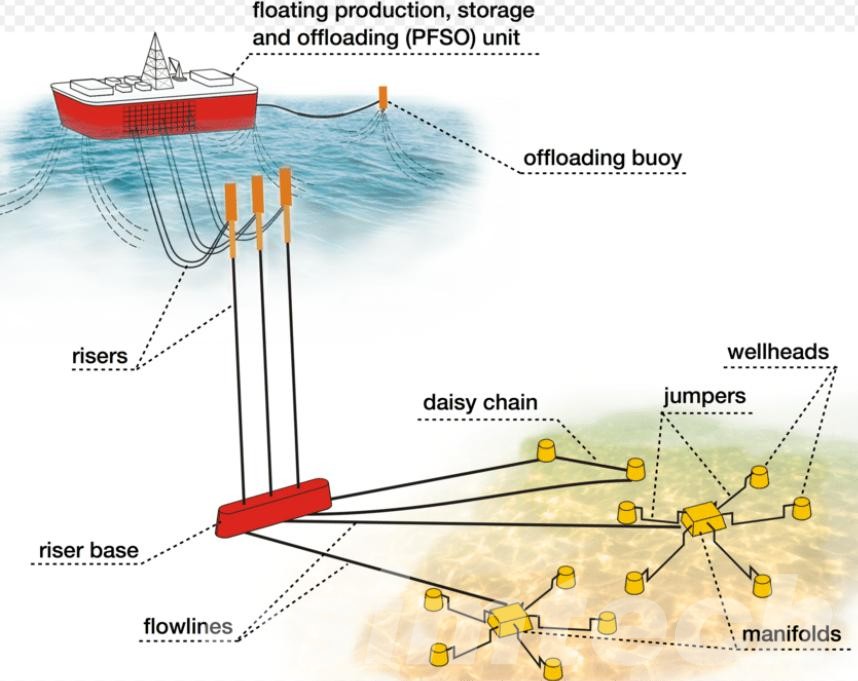

Offshore oil and gas development is becoming increasingly globalized and is moving into deeper waters. As technology matures, the demands on subsea production systems are also growing. These systems are characterized by high risks and significant investment costs, making safe and reliable technology, as well as high-performance equipment, crucial for their success.

Although subsea production technology is now relatively advanced worldwide, several challenges remain.

1. Challenges in Subsea Production Systems

Processing of Produced Fluids from Subsea Wells

With the widespread application of subsea production systems in offshore oil and gas fields, conventional oil and gas processing facilities installed on the surface or onshore are gradually moving underwater. This shift aims to truly achieve subsea processing of oil and gas, significantly improving recovery rates and extending the lifespan of oil and gas fields.

Selection of Subsea Equipment

The characteristics of oil and gas production in subsea systems place higher demands on the reliability and safety of subsea equipment. The harsh deep-sea environment, with high pressures and low temperatures, also requires equipment to have excellent pressure resistance and corrosion resistance. As offshore oil and gas development moves into deeper waters, subsea control systems have evolved from simple direct hydraulic control to modern electrohydraulic control. Ensuring the reliability of pipelines and equipment, and designing safe, reliable, and sensitive control and monitoring systems, remain key focuses of the industry.

Flow Assurance of Subsea Pipelines

Flow assurance in subsea pipelines is a core issue in offshore oil and gas development. Key challenges include:

- Reducing or inhibiting wax deposition, sand accumulation, hydrate formation, and severe slug flow;

- Developing rational shutdown and restart plans to minimize the impact on system integrity;

- Addressing uncertainties in the subsea environment;

- Minimizing or preventing corrosion of subsea pipelines.

2. Development of Subsea Production Systems

Current cutting-edge technologies in subsea production systems include long-distance flow assurance, subsea power transmission and all-electric control, subsea installation techniques, reliability and integrity management of subsea systems, and subsea production in polar regions. These systems are a comprehensive application of multidisciplinary high technologies, posing significant challenges to the research and development capabilities of both academic institutions and companies.

China has always placed great emphasis on offshore oil and gas development. As development targets shift from shallow waters like the Bohai Sea to deeper waters in the East China Sea and especially the South China Sea, the importance of subsea production systems is becoming more prominent. However, most core technologies in deep-sea oil and gas development are still held by foreign companies, and China lacks practical engineering experience, with a strong dependence on foreign technologies. Significant efforts are needed to achieve independent design of offshore oil and gas field development plans, localize subsea production systems, enhance technological and equipment levels, and reduce reliance on foreign technologies.

3. Recommendations for Future Development

To address these challenges, the following actions are recommended:

- Deep Study of Advanced Foreign Subsea Production Systems: Conduct thorough research on advanced foreign subsea production systems, fully grasp cutting-edge technologies, and adapt them to China's specific conditions to ensure the safety and reliability of the systems.

For more information on subsea production systems, please visit Esimtech.

Contact Information:

Phone: +86 28-68969592

Email: [email protected]

Address: No. 88 Xingle North Road, Xindu District, Chengdu, China